Housing is changing to meet new energy standards,

and so must our climate solutions

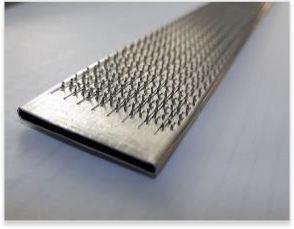

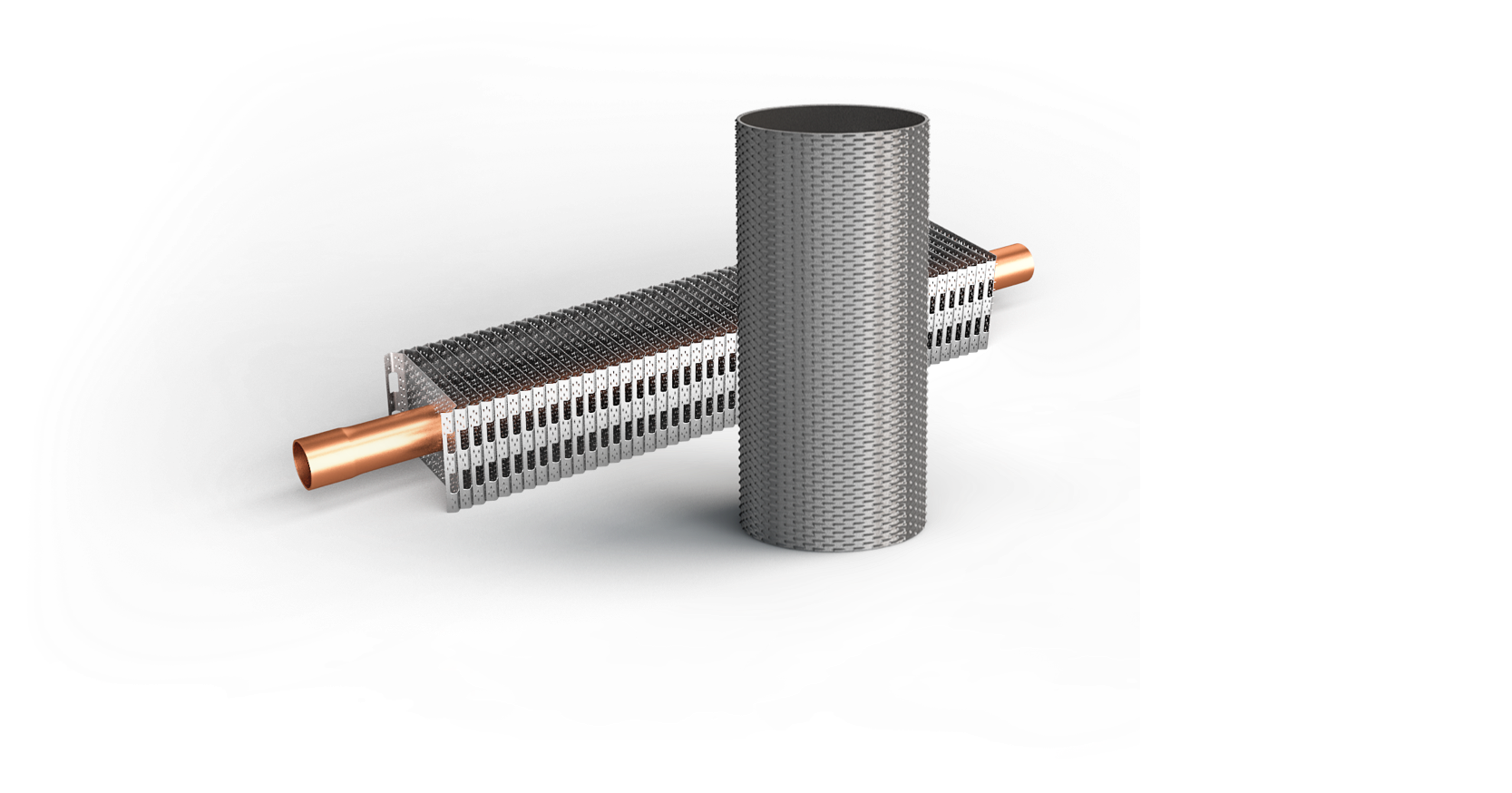

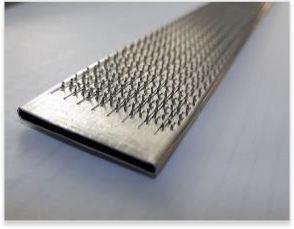

Using NUCAP’s surface modification delivers significant gains in efficiency for heat exchangers, ranging from 40% to more than 100% (for viscous media, like oils). Increased efficiency makes it possible to save money by reduceing the size and weight of heat exchangers.

Use of NUCAP’s surface modification allows for the fabrication of composite radiant panels, where enhanced material serves a double role, as radiating surface and as structural binding material. Due to the mechanical bond between the layers of NUCAP’s radiant panels there is no need for glues; this feature totally eliminates generation of volatile chemical vapours , The hooks' penetration of the surface layer of finishing material also increases heat transfer to the surface of the panel.

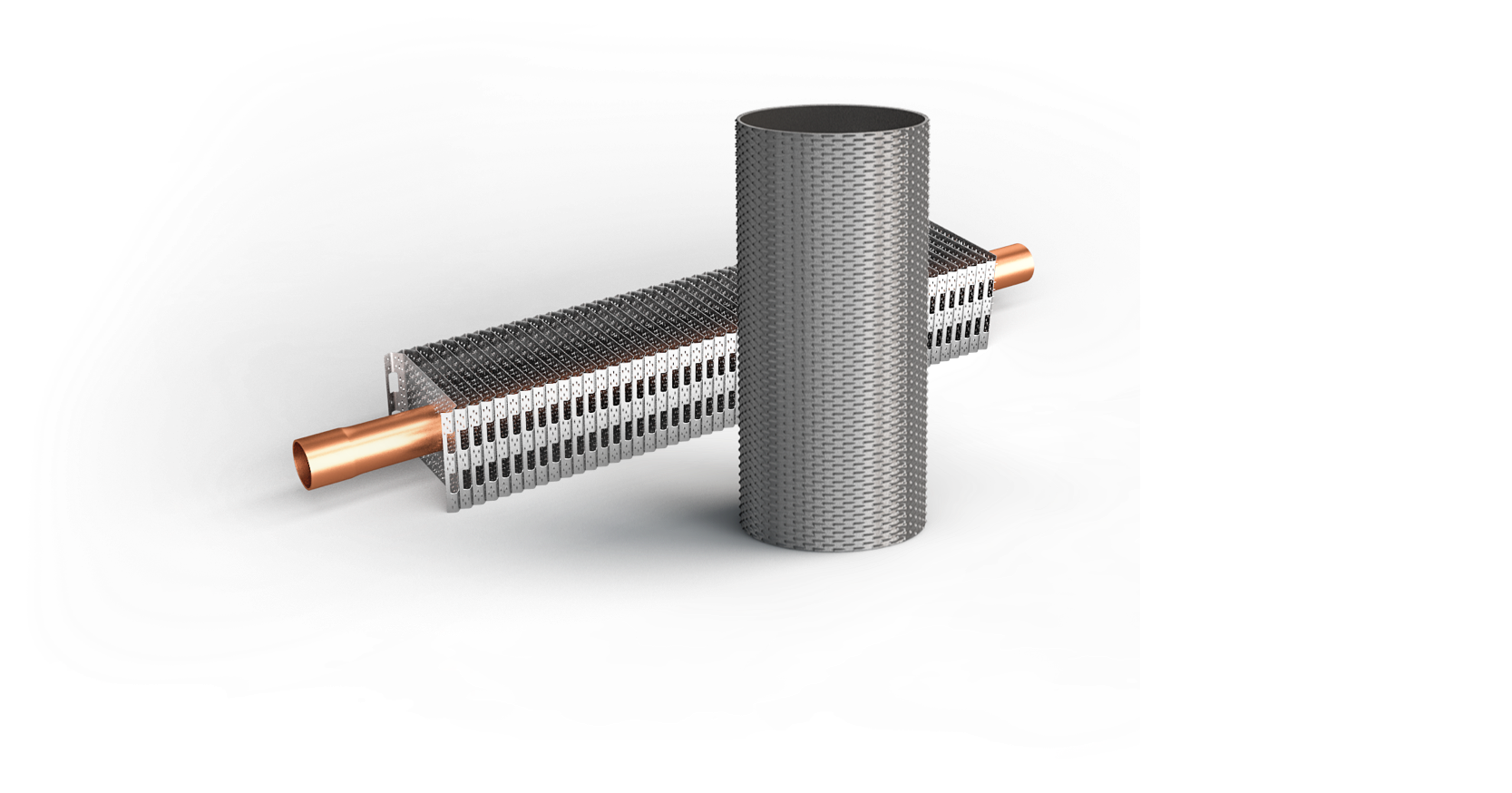

NUCAP’s enhanced surface material is used in different types of heat exchangers, from large rotary exchangers that are designed for venues like arenas, theatres, and hospitals, to crossflow exchangers used for heat recovery in single family houses, to hydronic plate exchangers used in industrial applications.

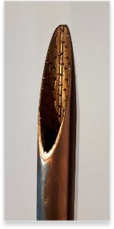

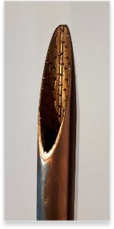

Pipes and tubes with enhanced surface (both internal and external) can be used in many HVAC applications, Particularly evaporators and condensers, as well for heat exchange in viscous liquids, providing the best results for increased efficiency in the heat exchange process.

NUCAP’s surface modification is exceptionally useful in phase change systems (thermal energy storage, heat pipes). The increased area of heat exchange and the hooks’ “penetration” into the layers of medium (fluid or solid) is paramount for efficiency gains in these systems.

Design for the Future, Outperform your Competition – Partner with NUCAP Energy

Fighting Pandemics (Current and Future Ones) by Retrofitting our Buildings with High Efficiency Ventilation Systems and Hydronic Heating

Properly built air-flow systems for public buildings (offices, schools) and private dwellings are a low-tech approach to fight the current and future pandemics. These systems should prevent cluster infections to allow people to safely work and learn in large groups in one room.

Currently most of the buildings in North America use hot air to heat the interior. All toxins, bacteria and viruses are just being spread by the hot air circulating inside the buildings. Hydronic heating in tandem with proper ventilation and heat recovery systems are positioned for the future vast market demand for retrofits.

GRIPMetal allows for a substantial improvement of efficiency of all these systems: radiant heating, ventilation, and heat recovery.

NUCAP Energy isn’t the only NUCAP family of companies fighting COVID-19. With their own individual efforts, other NUCAP divisions are doing their part to fight this pandemic.

Our Spidertech division has found a way to use its Kinesiology tape technology to create wearable face masks that are safe and easy to use. Because these masks are strapless they never fall or get out of place. See more at: www.spidertech.com

Our GRIPBlock division has developed a LEGO like building technology that’s helping our restaurants and schools stay safe. With social distancing shelters and walls. Just another way NUCAP technology making our public spaces safe again. See more at: www.gripblock.com