FOR ALL INQUIRIES: Contact Us at info@nucapenergy.com

NUCAP technology offers many advantages over traditional

materials used in energy applications across a variety of industries

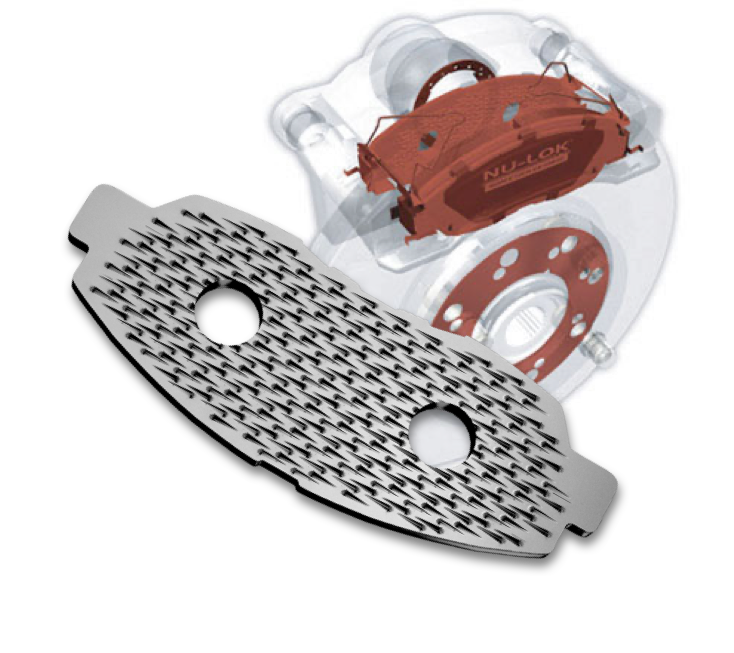

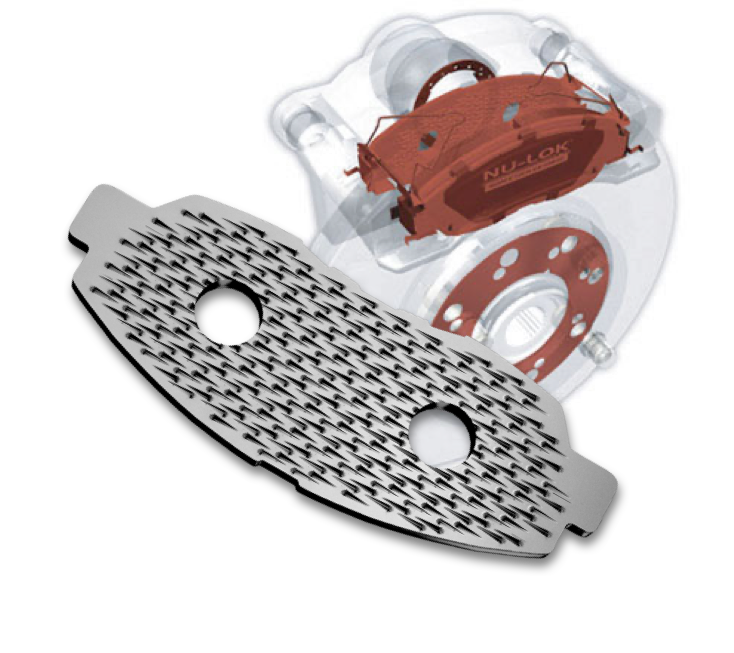

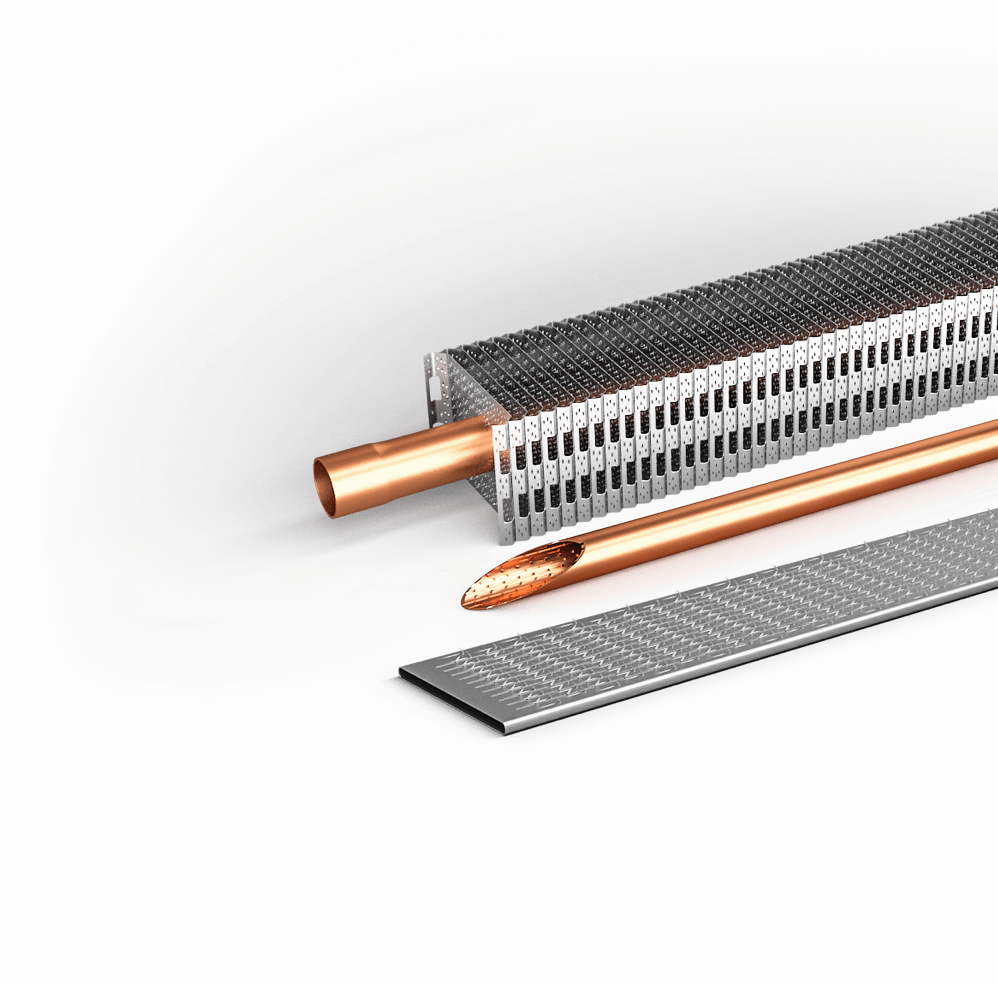

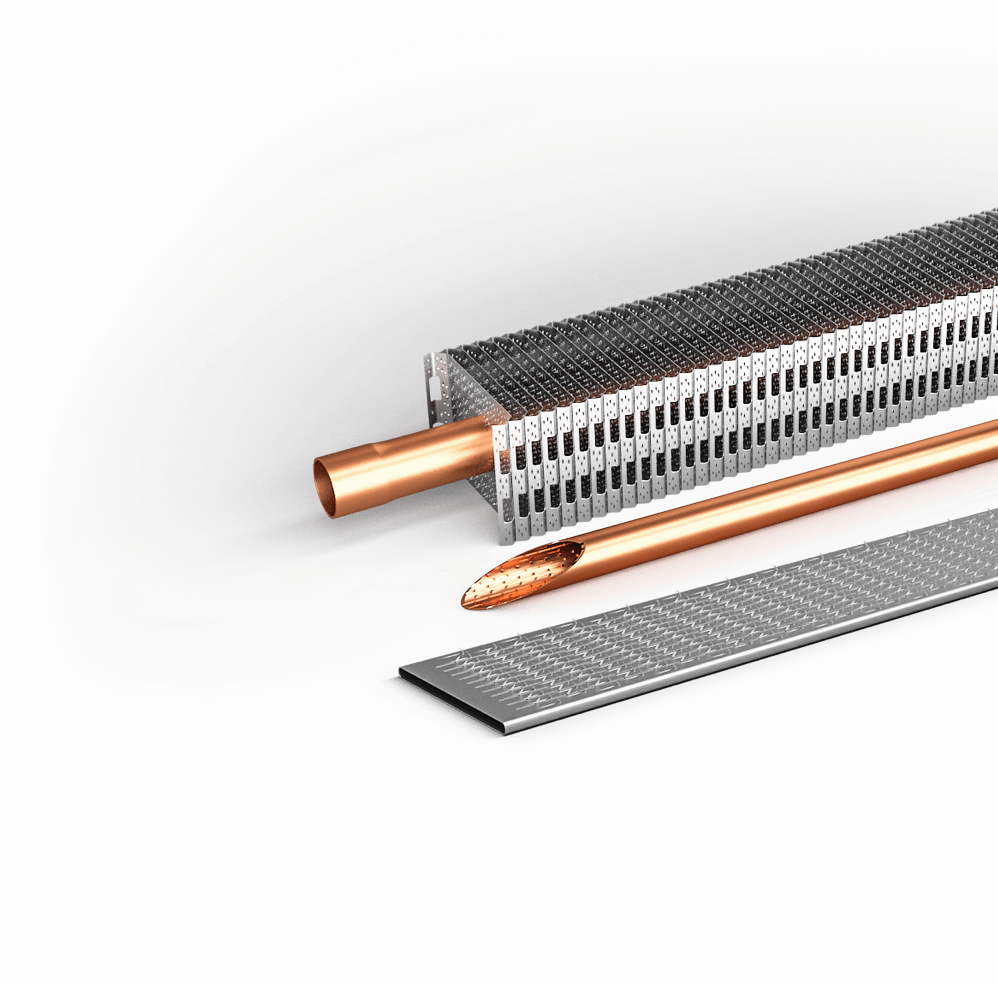

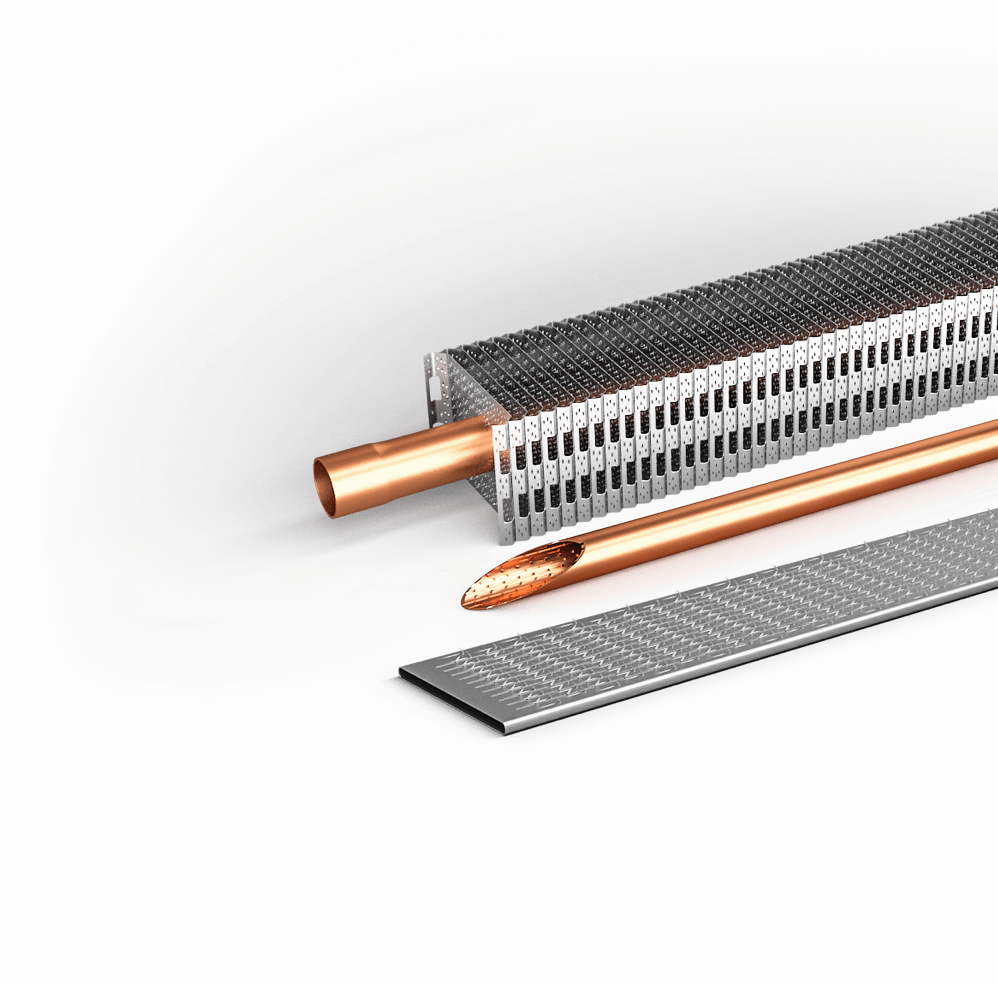

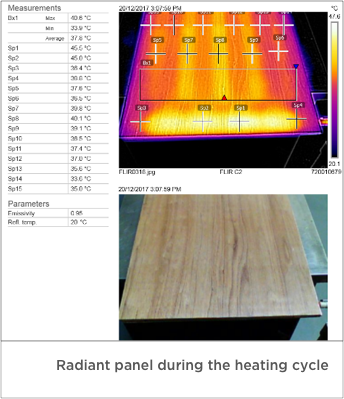

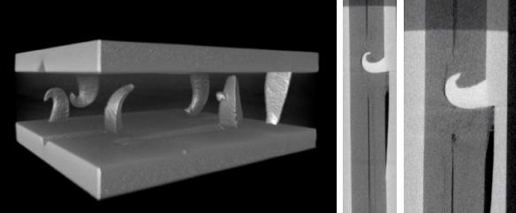

The original technology of surface modification was developed by NUCAP, our parent company. The technology of surface modification has been employed for over 21 years in high-performance automotive brake systems, where NUCAP’s brake pads withstand extreme temperature changes and aggressive environments. The signature metal teeth are used to firmly bond components made from different materials, so as they are inseparable across the entire surface of contact in ways that adhesive bonds cannot match.

NUCAP Energy uses surface modification to improve the efficiency of thermal processes. Our goal is to reduce the size and weight of heat exchange devices while increasing their efficiency and structural strength. Our technology supports a growing number of innovations in aerospace, transportation, computing, HVAC, power and renewable energy, among other key industries.

Substantial changes in size, weight and efficiency of existing products can transform entire industries and create a more sustainable future, thanks to innovations from NUCAP Energy, from zero-gravity heat exchangers for spacecraft to better performance of electric vehicles.

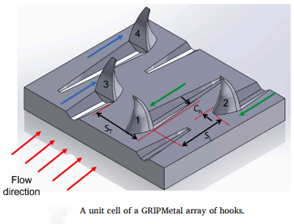

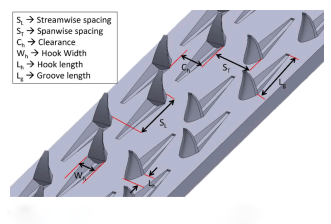

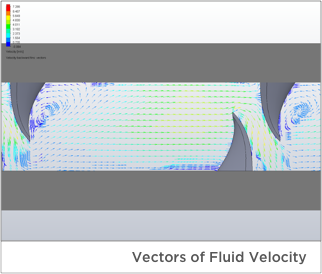

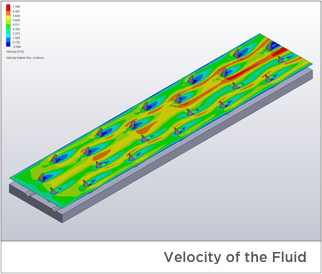

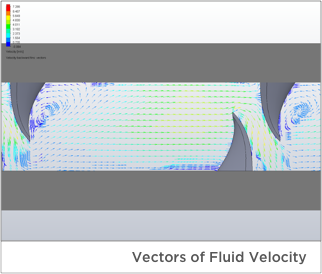

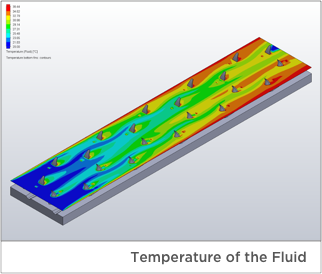

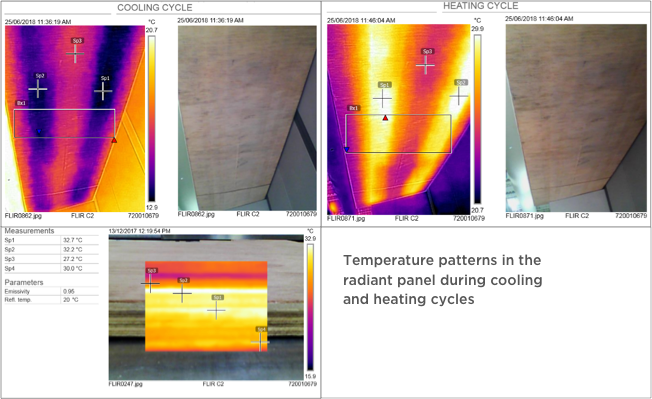

Our surface improvement increases heat exchange efficiency for all three forms of thermal energy transfer: convection, conduction, and radiation. GRIPMetal is an ideal interface between any combination of heat transfer media: gases, liquids, and solids.

We work with universities and researchers from different industries to hone our engineered metal surface enhancement. Below we present some of our current projects.

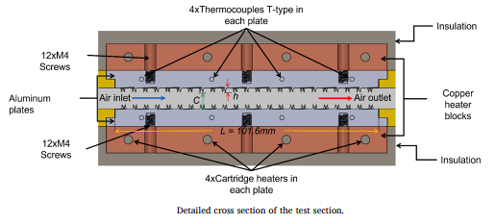

In collaboration with Prof. Roger Kempers, York University’s TF-Lab, and in conjunction with NSERC,

NUCAP Energy is improving the engineering behind the process of heat exchange.

In collaboration with Prof. Roger Kempers, York University’s TF-Lab, and in conjunction with NSERC,

NUCAP Energy is improving the engineering behind the process of heat exchange.

Roger Kempers, Department of Mechanical Engineering,

York University, Toronto, Canada

John Swift, NUCAP Energy, Toronto, Canada

Roger Kempers, Department of Mechanical Engineering,

York University, Toronto, Canada

John Swift, NUCAP Energy, Toronto, Canada

Omar Khaled, Department of Mechanical Engineering,

York University, Toronto, Canada

Roger Kempers, Department of Mechanical Engineering,

York University, Toronto, Canada

John Swift, NUCAP Energy, Toronto, Canada

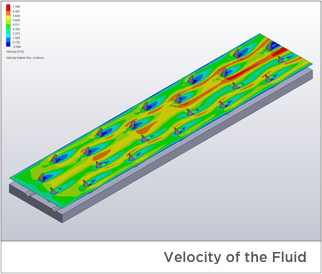

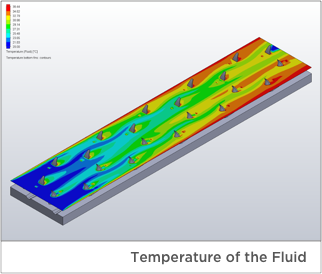

Ahmed Elkholy, Mechanical Engineering, York University, Toronto

Roger Kempers, Mechanical Engineering, York University, Toronto

John Swift, NUCAP Energy, Toronto, Canada

Omar Khaled, Department of Mechanical Engineering, York University, Toronto

Roger Kempers, Department of Mechanical Engineering, York University, Toronto

John Swift, NUCAP Energy, Toronto, Canada

Mohammad Emamjome Kashan, Department of Mechanical and Industrial Engineering, Toronto Municipal University (previously Ryerson University)

Alan S. Fung, Department of Mechanical and Industrial Engineering, Toronto Municipal University (previously Ryerson University)

John Swift, NUCAP Energy, Toronto, Canada

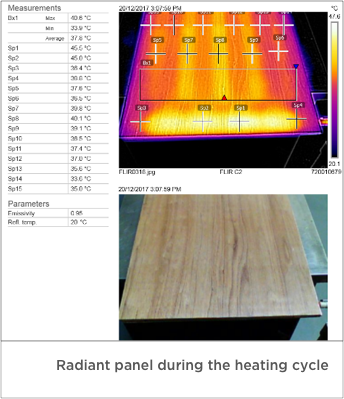

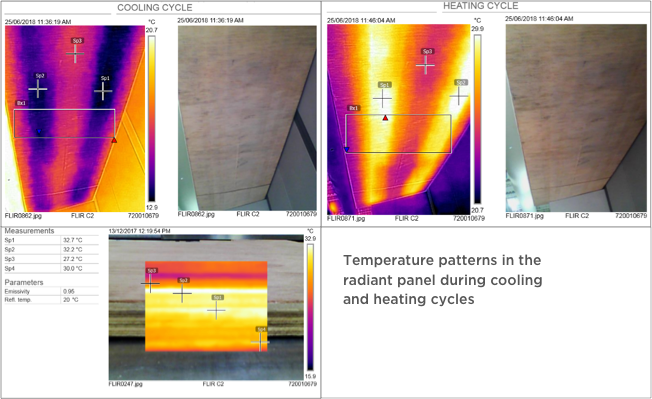

Working closely with Prof. Seth B. Dworkin and the lab at Ryerson University in partnership with NSERC, NUCAP

Energy is looking at improving technologies for residential environment systems

Seth Dworkin, S. Shukla, R. Daneshazarian, A. Mwesigye, Mechanical and Industrial Engineering Department, Ryerson University, Toronto, Canada

John Swift, NUCAP Energy, Toronto, Canada

Seth Dworkin, S. Shukla, R. Daneshazarian, A. Mwesigye, Mechanical and Industrial Engineering Department, Ryerson University, Toronto, Canada

John Swift, NUCAP Energy, Toronto, Canada

Professor Dr. Reinhard Schlitt

Richard Schlitt Engineering

Services

Bremen, Germany

"We discovered GRIPMetal as a superb element in our development of hybrid structures to improve heat exchange in spacecraft designs. Our new and mass-saving hybrid compound is composed of thermally high conductive carbon layers sandwiched between GRIPMetal sheets. GRIPMetal provides the required mechanical strength and the hooks penetrating into the layers increase substantially the out-of-plane thermal conductivity.

Test results confirm that the new GRIPMetal structure considerably improves heat exchange in spacecraft applications such as in passive thermal radiators, thermal doublers and housings of power electronics. The use of GRIPMetal will lead in this way to outstanding weight and cost reduction in various spacecraft thermal management systems."

Design for the Future, Outperform your Competition – Partner with NUCAP Energy

Fighting Pandemics (Current and Future Ones) by Retrofitting our Buildings with High Efficiency Ventilation Systems and Hydronic Heating

Properly built air-flow systems for public buildings (offices, schools) and private dwellings are a low-tech approach to fight the current and future pandemics. These systems should prevent cluster infections to allow people to safely work and learn in large groups in one room.

Currently most of the buildings in North America use hot air to heat the interior. All toxins, bacteria and viruses are just being spread by the hot air circulating inside the buildings. Hydronic heating in tandem with proper ventilation and heat recovery systems are positioned for the future vast market demand for retrofits.

GRIPMetal allows for a substantial improvement of efficiency of all these systems: radiant heating, ventilation, and heat recovery.

NUCAP Energy isn’t the only NUCAP family of companies fighting COVID-19. With their own individual efforts, other NUCAP divisions are doing their part to fight this pandemic.

Our Spidertech division has found a way to use its Kinesiology tape technology to create wearable face masks that are safe and easy to use. Because these masks are strapless they never fall or get out of place. See more at: www.spidertech.com

Our GRIPBlock division has developed a LEGO like building technology that’s helping our restaurants and schools stay safe. With social distancing shelters and walls. Just another way NUCAP technology making our public spaces safe again. See more at: www.gripblock.com