For Unmatched Thermal

and Structural Performance

(In Composites)

(Structural + Thermal)

Without increase of gross material weight

With supreme mixing capability

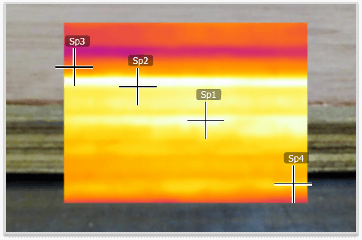

Enhanced heat conductivity

in composite materials

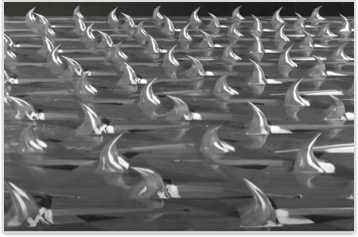

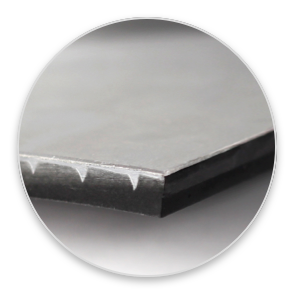

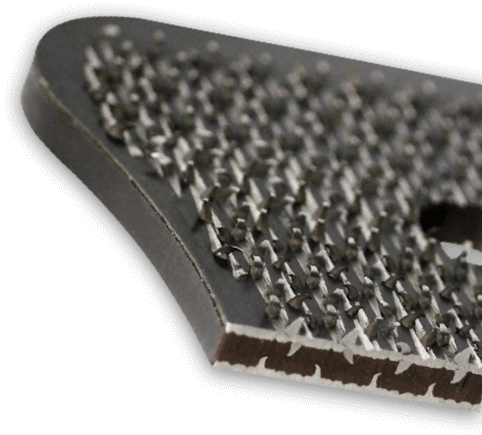

Conductivity between layers of a composite material is increased substantially by thousands of hooks penetrating adjacent materials, increasing the overall rate of heat transfer.

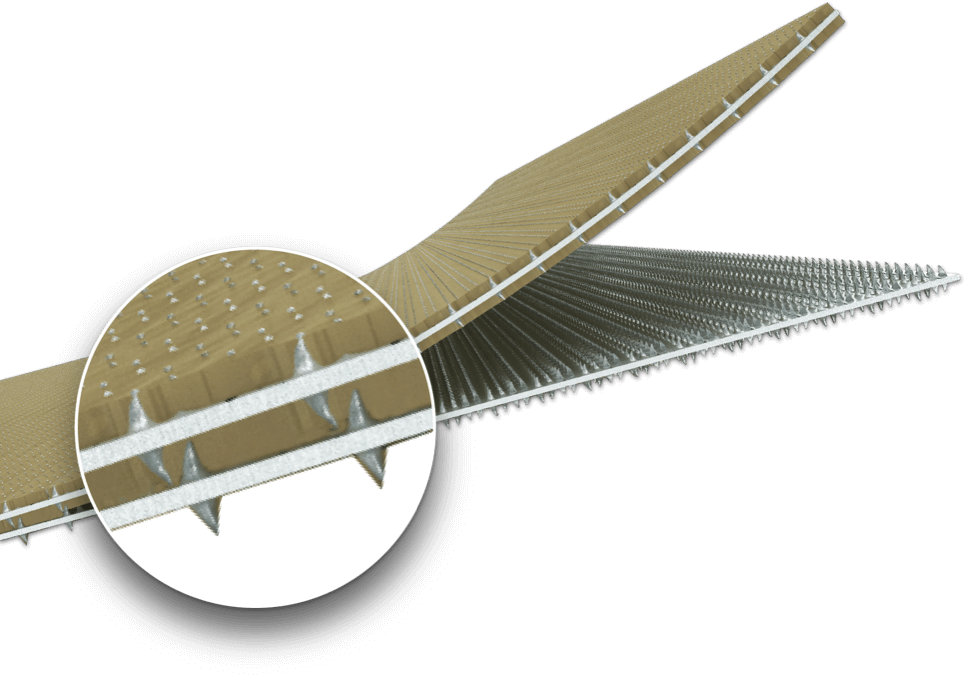

The hooks permanently bond materials to the metal surface. These materials will never separate.

Fragile materials are reinforced by layer(s) of GRIPMetal to deliver overall strength and moldability of the composite.

The structural and thermal features of the metals’ surface enhancement allow for creation of composite materials with superior heat exchange qualities, as well as low weight and increased strength when compared with other contemporary materials.

Our unique and patented process that creates surface enhancement increases surface area without adding weight to an element, which allows manufacturers to reduce the size and weight of their products.

we provide complete support for your product or application

Our expert manufacturing and product design teams can assist in the design and production of limitless solutions.

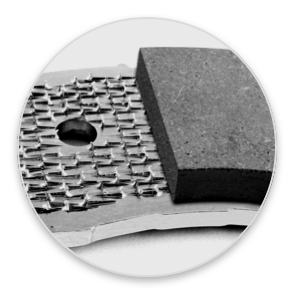

From brake pads to new thermal transfer technology.

Our technology has been successfully applied in more than 1 billion brake pads installed in cars and trucks for the last 21 years to connect friction material with the steel backing plates.

Now we apply our extensive expertise and state-of-the-art manufacturing technology to improve heat transfer and storage processes.

GRIPMetal bonds brakes' friction material to steel backing plate and every day survives one of the harshest conditions – these are our CREDENTIALS

NRS Licensees

NRS/GRIPMetal Manufacturing Sites

India

United Kingdom

Vietnam / Taiwan

Brazil

Spain / China

Denmark

India

Japan / Thailand

Design for the Future, Outperform your Competition – Partner with NUCAP Energy

Fighting Pandemics (Current and Future Ones) by Retrofitting our Buildings with High Efficiency Ventilation Systems and Hydronic Heating

Properly built air-flow systems for public buildings (offices, schools) and private dwellings are a low-tech approach to fight the current and future pandemics. These systems should prevent cluster infections to allow people to safely work and learn in large groups in one room.

Currently most of the buildings in North America use hot air to heat the interior. All toxins, bacteria and viruses are just being spread by the hot air circulating inside the buildings. Hydronic heating in tandem with proper ventilation and heat recovery systems are positioned for the future vast market demand for retrofits.

GRIPMetal allows for a substantial improvement of efficiency of all these systems: radiant heating, ventilation, and heat recovery.

NUCAP Energy isn’t the only NUCAP family of companies fighting COVID-19. With their own individual efforts, other NUCAP divisions are doing their part to fight this pandemic.

Our Spidertech division has found a way to use its Kinesiology tape technology to create wearable face masks that are safe and easy to use. Because these masks are strapless they never fall or get out of place. See more at: www.spidertech.com

Our GRIPBlock division has developed a LEGO like building technology that’s helping our restaurants and schools stay safe. With social distancing shelters and walls. Just another way NUCAP technology making our public spaces safe again. See more at: www.gripblock.com